Filtration Basics 101 begins with understanding ISO Cleanliness Codes & Oil Contamination basics

What is an ISO Cleanliness Code? An ISO Cleanliness Code is a standard which was developed by the International Standardization Organization (ISO) to measure how many contaminants are in oil and what size they are. Filtration Basics.

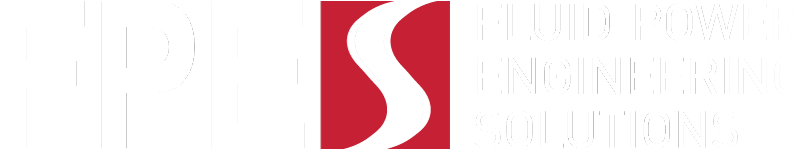

The ISO Code depicts contamination levels per millilitre of fluid at 3 different sizes: 4microns, 6microns and 14microns.

Each number in the three part code ≥4 ≥ 6 ≥14, shows the contaminant level for that corresponding particle size (including all particles equal too and greater then).

What does this mean for you?

It doesn’t take much to contaminate clean oil.

A common cleanliness code for newe oil is 22/21/18 or higher, this is NOT suitable for most hydraulic and lubrication equipment which operate on finer tolerances of 16/14/11 or cleaner.

This shows the importance of filtering new oil to avoid breakdowns and equipment damage.

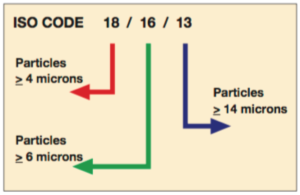

Magnification of oil samples showing

particulate at various ISO Codes

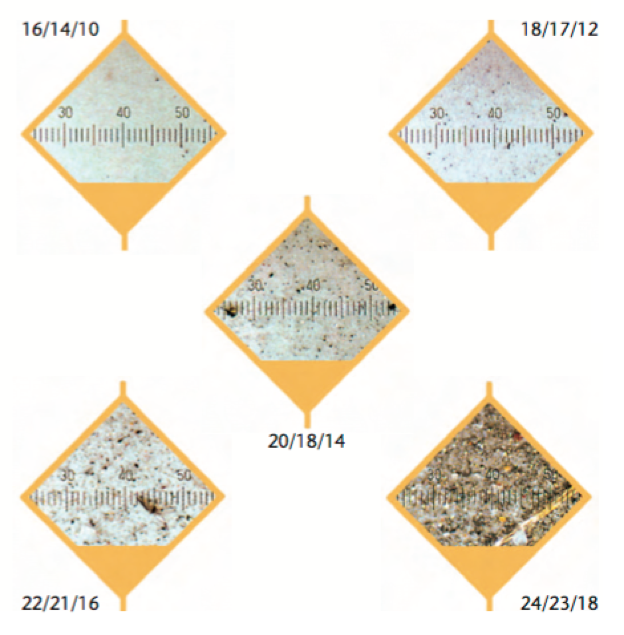

The benefits of filtration basics are probably best presented by comparing the impact on the same system operating with varied cleanliness codes.

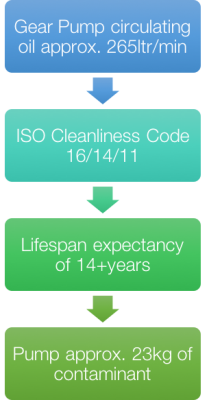

Consider the following example of a gear pump, circulating oil at 265ltrs/min;

Gear Pump 1

A cleanliness level of approximately ISO 22/21/18

Gear Pump 2

Circulating oil cleaned to ISO 16/14/11

Types of Contaminants

Contaminants can be in the form of dust, dirt, worn out metallic parts, rubber, sand, water, air, chemical residuals, oxidisation.

Sources of Contamination

- Application borne contaminants – during system operation through worn seals and other system openings, metal chips, dirt, dust debris generated by the application or manufacturing process

- System borne contaminants – by products of wear generated within the hydraulic system; abrasive, cavitation, fatigue, erosive, corrosive, adhesive wear

- Maintenance borne contaminants – which are introduced through equipment service, opening and closing system components like valve, pipe, hosing, fittings, breather caps, cylinder rod glands etc

Contamination Causes

Contamination is the major cause of hydraulic related breakdowns; particulate, moisture, varnish build up all contribute to;

- accelerated abrasive wear on bearings

- seal degradation system leaks

- corrosion of metal surfaces

- increased electrical conductivity

- fluid oxidisation

- viscosity variance

- loss of lubricity

- additive depletion

- unscheduled breakdowns

- high maintenance costs

- component replacement costs

- shortened equipment life

- premature capital costs

Working to Correct Fluid Cleanliness Targets will;

- reduce downtime

- reduce repair expenses

- reduce maintenance hours

- reduce costly unnecessary component replacement

- extend machine/equipment life

- maximise uptime

- optimise profits

Don’t want to be an expert at Filtration and prefer to spend time focused on your business?

Lean on our FluidCare™ technicians who can give you valuable advice tailored to your requirements call 1300 883 995 or info@fluidcare.com.au